Established in 2017, our team of professional engineers, designers and consultants bring together expertise, powerful technologies and a wealth of industry experience as a growing engineering consultancy in the UK that solves problems.

Our culture, setup and experience are tailored to working on high integrity systems within highly regulated industries while having to deliver to challenging timescales and budgets. Our verification processes follow the requirements of our ISO 9001 QMS and are compatible with those companies which operate in highly regulated industries.

We offer an extensive range of professional engineering consultancy & design services to UK businesses.

Our Engineering Expertise

Working with DOCAN's consulting engineers

We bring expertise, powerful technologies, industry experience and unrivalled insights to help our clients solve their engineering problems and challenges.

We work in a way that suits our clients, with a flexible approach that allows us to get involved in as much or as little of their project as they require. Our clients choose us when they lack the in-house skills or resources to effectively overcome a challenge, or when they require a cutting-edge solution that only DOCAN can deliver.

Our knowledge and expertise are transferrable across multiple industries and applicable to applications both large and small. We approach every project with a can-do attitude so whatever engineering challenge you’re struggling to identify and overcome, we can help.

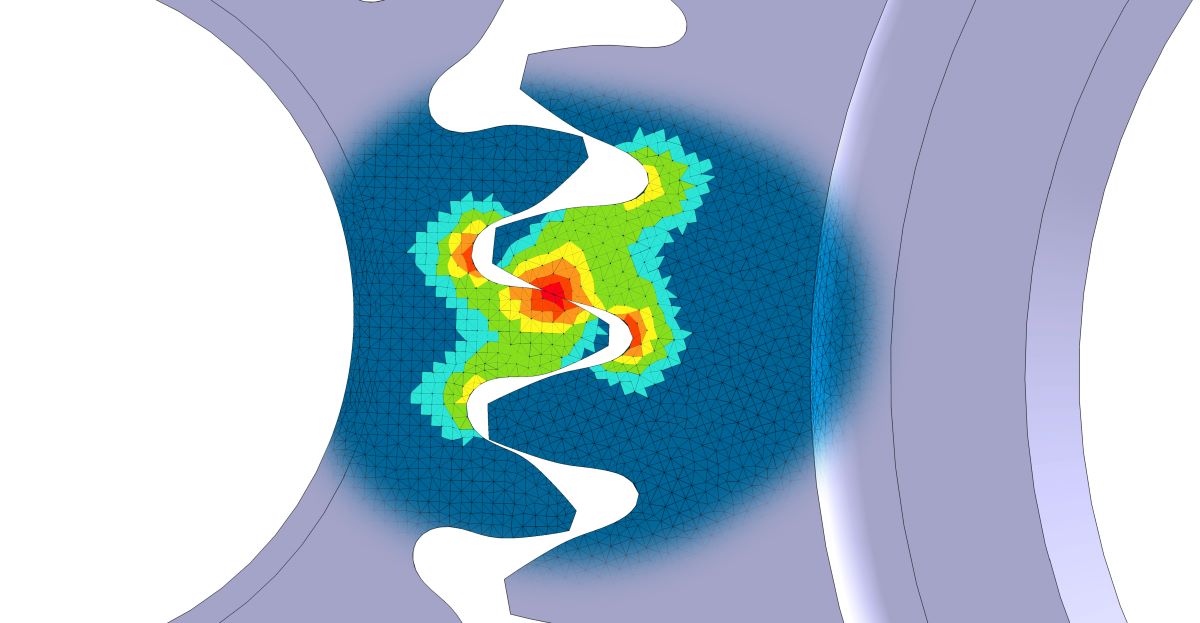

Our engineering software

In addition to our partnerships with leading software vendors, we have access to and experience with a wide range of design and simulation products.

If you require a consultancy project to be completed with a specific tool please get in touch to discuss your requirements.